cnc machining or 3d printing 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making . Find and Compare Sheet Metal Fabricators near MARRICKVILLE, NSW. Get Reviews, Location and Contact details.From structural steel to industrial ladders to high-quality production components for some of the nation’s top manufacturers, UMFI is known for our versatility and expertise. We're committed .

0 · subtractive manufacturing 3d printing

1 · mostly 3d printed cnc

2 · diy 3d printer lathe cnc

3 · cnc machine vs 3d printer

4 · 3d printing milling machine

5 · 3d printer diy cnc milling

6 · 3d printed cnc mill

7 · 3d printable cnc machine

Cylinder Shaped Coin Collection Box is an cylinder shaped tall coin collection box designed by My Charity Boxes for multi-purpose coin collections. Its specialty is that with its unique, sleek design, it stores neatly on desktops, shelves, and store counters for easy access.

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. See more CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds .Explore the key differences between CNC machining and 3D printing, including their strengths, weaknesses, and ideal use cases to choose the right process for your project. 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making .

CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar .

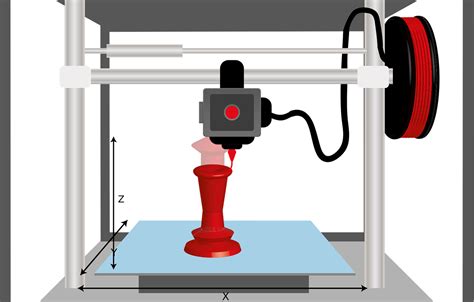

3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). . When you want to create a new part, there are two manufacturing methods you can turn to: CNC machining and 3D printing. Although both processes are standard today, each .

installing a junction box in ceiling without studs

Both CNC machining and 3D printing have pivotal roles in prototyping for industries like aerospace, robotics, and construction. CNC machining excels in producing highly accurate and smooth parts, making it ideal for components .

CNC machining and 3D printing offer distinctive approaches in manufacturing, each with its own set of advantages and considerations. CNC machining, characterized by its subtractive nature, excels in producing high-quality .Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds material layer by layer.

Explore the key differences between CNC machining and 3D printing, including their strengths, weaknesses, and ideal use cases to choose the right process for your project.

3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications. This article discusses a detailed review and a distinction between CNC machining vs 3D printing.3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). 3D printing doesn’t require special tooling or fixtures, so the initial setup cost is minimal compared to CNC machining. Other 3D printing advantages . When you want to create a new part, there are two manufacturing methods you can turn to: CNC machining and 3D printing. Although both processes are standard today, each has evolved to meet different demands — so it’s important to know .

Both CNC machining and 3D printing have pivotal roles in prototyping for industries like aerospace, robotics, and construction. CNC machining excels in producing highly accurate and smooth parts, making it ideal for components that require precise dimensions.CNC machining and 3D printing offer distinctive approaches in manufacturing, each with its own set of advantages and considerations. CNC machining, characterized by its subtractive nature, excels in producing high-quality prototypes and final .

CNC machining can produce parts with tight tolerances and better ensure consistency across large production runs. 3D printing, on the other hand, is better suited for smaller, intricate parts with complex geometries.Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds material layer by layer.Explore the key differences between CNC machining and 3D printing, including their strengths, weaknesses, and ideal use cases to choose the right process for your project.

3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications. This article discusses a detailed review and a distinction between CNC machining vs 3D printing.3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). 3D printing doesn’t require special tooling or fixtures, so the initial setup cost is minimal compared to CNC machining. Other 3D printing advantages .

install outdoor light junction box

When you want to create a new part, there are two manufacturing methods you can turn to: CNC machining and 3D printing. Although both processes are standard today, each has evolved to meet different demands — so it’s important to know .

Both CNC machining and 3D printing have pivotal roles in prototyping for industries like aerospace, robotics, and construction. CNC machining excels in producing highly accurate and smooth parts, making it ideal for components that require precise dimensions.

CNC machining and 3D printing offer distinctive approaches in manufacturing, each with its own set of advantages and considerations. CNC machining, characterized by its subtractive nature, excels in producing high-quality prototypes and final .

installing junction box for chandelier

subtractive manufacturing 3d printing

Truck rear-axle machining in one set-up High accuracy High speed Fewer machines and less floor space Request a quotation

cnc machining or 3d printing|3d printable cnc machine